DONGGUAN YIXUN INDUSTRIAL CO., LTD.

Mob: +86 13829193570

E-mail: caobin@yixun-dg.com

DONGGUAN YIXUN INDUSTRIAL CO., LTD.

Mob: +86 13829193570

E-mail: caobin@yixun-dg.com

The advantage for -gas assisted injection molding :

low injection pressure

a small deformation of the part

good surface quality

the thick part of the product is hollow,reducing plastic up to 40%

get quotation pls contact joyce@yixun-dg.com,mobile phone :+8615011735274

PRODUCT DESCRIPTION

product details

| Place of Origin | Guangdong, China |

| Brand Name | YIXUN MOLD FACTORY |

| Shaping Mode | Plastic Injection Mould |

| Product Material | steel |

| Plastic Material | PP,PC,PA,PA6,ABS,PET,PVC,POM,.etc |

| Gate system | Cold Runner/Hot Runner |

| Ejection | Pin/Stripper Plate.etc |

| A.B plate | 1.1730/P20.etc |

| Tool Life | Prototype~1,000,000 shots |

| Mold Base | LKM stand moldbase + copy HASCO components |

| Cavity&Core | P20/H13/NAK80/S50C/S136/738H.etc |

| Surface Finish | Polish/Texture/Heat Treatment.etc |

| Cavities | Single/Multiple/Family mold Lead Time: 3~8 weeks |

We provides ONE-STOP SERVICE for plastic product customizing works,

We provide mold design,precision plastic mold making,

custom best quality plastic injection molding,

Assembly Work, Pad Printing, Silk Screen Print, Paint, Ultrasonic Welding and Packaging Services.

Tooling making and injection workshop

Dongguan YIXUN Industrial Co.,Ltd is a high technology company,specializing in many kinds of plastic mold designing,manufacturing and injecting,mainly covering the enclosure and part of automobile,electrical,printer,commodity,electronic etc.

YiXun has 2 manufacturing facilities, totally 12,000 square meters, 260 employees, 90% of them has experience over 10 years.YiXun yearly capability is up to 600 sets mold per year, the biggest reach 25 tons.

YiXun adopt the up-to-date design software, such as Auto CAD, UG, Pro/E, Solid Works etc, Mould standards such as DME, HASCO,FUTABA, LKM and so on.

YiXun has a full set advanced mould manufacturing equipment, 8 sets CNC machines, 15 sets EDM machine, 3 sets middle speed Wire Cut Machine, 2 sets slow speed Wire Cut Machine, 15 sets Milling Machine, 4 sets lathe machine, 2sets mold die fitting machine,17sets injection machine from 35 tons to 818 tons.

How to inquiry ?

Contact : joyce

Tel: +86 769 8155 0128 ext 20

Fax: +86 769 8155 0118

E-mail: joyce@yixun-dg.com

our ceritification

ISO 9001:2015 TIAF 16949

PRODUCTS SHOW

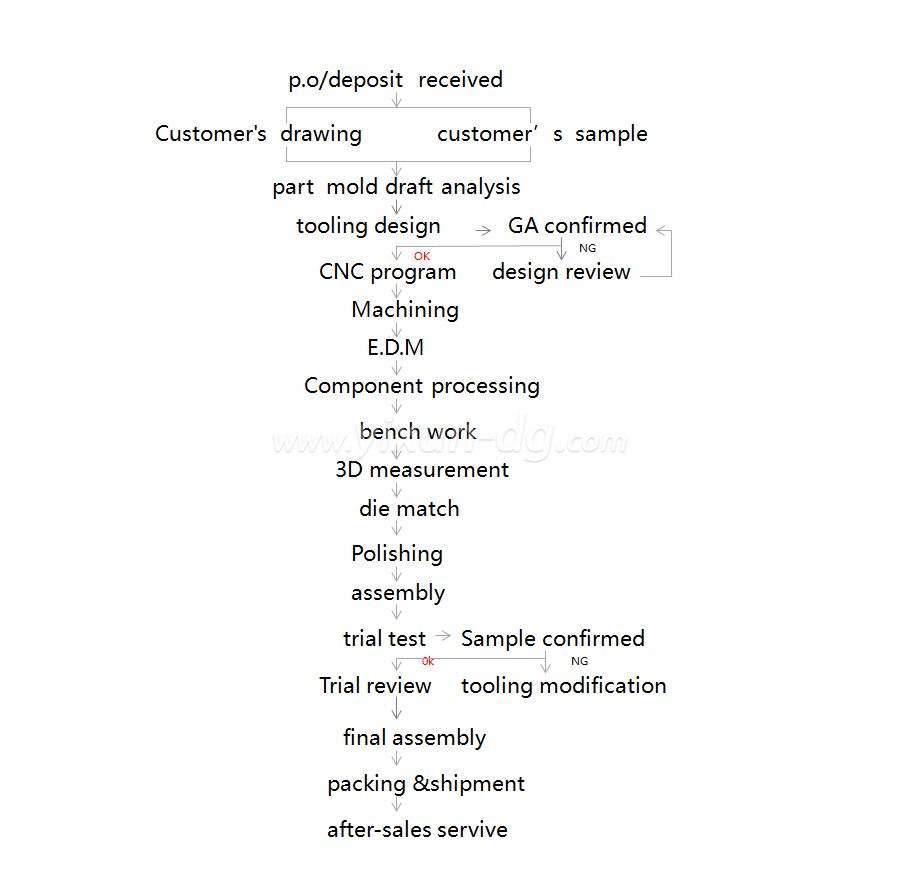

project management

product packaging

Mold FAQ

Q:How about your quality control?

A:We have professional team to control mold quality, since we realize that quality control is the first priority to run business.

Q:What's your lead time?

A:For most mold, 45 to 60 working days ( not including Chinese official holidays ) after deposit received and mold drawings approved.

Q:How long can I get the sample?

A:Depends on your specific items,within 3-7 days is required generally.

Q:What about after service?

A:Spare part which is non-man made damaged will be offered for free within one year, and you can contact us at any time if you need help.

NAVIGATION

Tel: +86 13829193570

E-mail: caobin@yixun-dg.com

Skype: info@yixun-dg.com

QQ: 1797581743

Add: No.8, Lane 1, Xiju Road, Hengli Town, Dongguan City, Guangdong Province,China

FOLLOW US